50+ pages using the assembly line balancing procedure 810kb. E is the answer because theres. Asked Aug 16 2019 in Business by tbdbt. 0104 50 96 480 Cannot be determined from the information above Which of the following are among the major reasons that exponential smoothing has become. Check also: balancing and learn more manual guide in using the assembly line balancing procedure Using the assembly-line balancing procedure which of the following is the required cycle time in minutes per unit if the daily production time is 2500 minutes and the required daily output is 50 units.

Advocard 28 10 months ago. Using the assembly-line balancing procedure which of the following is the theoretical minimum number of workstations if the task times for the six tasks that make up the job are 4 6 7 2 6 and 5 minutes and the cycle time is 10 minutes.

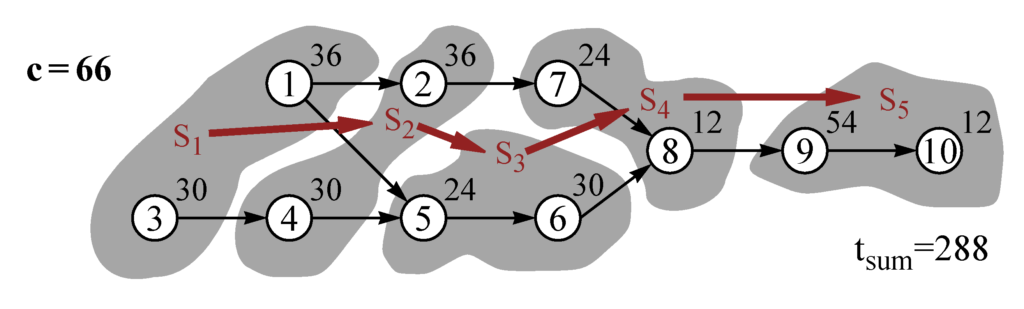

Precedence Diagram Of Assembly Work For Illustration Download Scientific Diagram

| Title: Precedence Diagram Of Assembly Work For Illustration Download Scientific Diagram |

| Format: ePub Book |

| Number of Pages: 295 pages Using The Assembly Line Balancing Procedure |

| Publication Date: April 2019 |

| File Size: 1.1mb |

| Read Precedence Diagram Of Assembly Work For Illustration Download Scientific Diagram |

|

Cannot be determined from the information given.

Production time is 480 minutes and the required daily output is 50 units. A- 480 b- 0104 c- Cannot be determined from the information above d- 50 e- 96. Here the job is divided into small portion. This can be performed by equalizing the amount of work in each station and assign the smallest number of workers in the particular workstation. Largest candidate rule method through spreadsheet simulation was used for tasks reallocations with the objective to minimize the cycle time when the number of stations is xed. Takt time is the rate at which parts or products must be produced in order to meet customer demand.

Flexible Multi Manned Assembly Line Balancing Problem Model Heuristic Procedure And Lower Bounds For Line Length Minimization Sciencedirect

| Title: Flexible Multi Manned Assembly Line Balancing Problem Model Heuristic Procedure And Lower Bounds For Line Length Minimization Sciencedirect |

| Format: eBook |

| Number of Pages: 167 pages Using The Assembly Line Balancing Procedure |

| Publication Date: July 2018 |

| File Size: 2.1mb |

| Read Flexible Multi Manned Assembly Line Balancing Problem Model Heuristic Procedure And Lower Bounds For Line Length Minimization Sciencedirect |

|

Pdf Modelling Of Simple Assembly Line Balancing Problem Type 1 Salbp 1 With Machine And Worker Constraints

| Title: Pdf Modelling Of Simple Assembly Line Balancing Problem Type 1 Salbp 1 With Machine And Worker Constraints |

| Format: eBook |

| Number of Pages: 164 pages Using The Assembly Line Balancing Procedure |

| Publication Date: March 2020 |

| File Size: 2.3mb |

| Read Pdf Modelling Of Simple Assembly Line Balancing Problem Type 1 Salbp 1 With Machine And Worker Constraints |

|

Assembly Line Balancing

| Title: Assembly Line Balancing |

| Format: ePub Book |

| Number of Pages: 191 pages Using The Assembly Line Balancing Procedure |

| Publication Date: March 2018 |

| File Size: 3mb |

| Read Assembly Line Balancing |

|

What Is Line Balancing How To Achieve It Tulip

| Title: What Is Line Balancing How To Achieve It Tulip |

| Format: ePub Book |

| Number of Pages: 237 pages Using The Assembly Line Balancing Procedure |

| Publication Date: October 2017 |

| File Size: 1.5mb |

| Read What Is Line Balancing How To Achieve It Tulip |

|

Salbp Assembly Line Balancing

| Title: Salbp Assembly Line Balancing |

| Format: eBook |

| Number of Pages: 239 pages Using The Assembly Line Balancing Procedure |

| Publication Date: May 2017 |

| File Size: 810kb |

| Read Salbp Assembly Line Balancing |

|

What Is Line Balancing

| Title: What Is Line Balancing |

| Format: PDF |

| Number of Pages: 154 pages Using The Assembly Line Balancing Procedure |

| Publication Date: December 2021 |

| File Size: 1.7mb |

| Read What Is Line Balancing |

|

Multi Objective Assembly Line Balancing Considering Ponent Picking And Ergonomic Risk Sciencedirect

| Title: Multi Objective Assembly Line Balancing Considering Ponent Picking And Ergonomic Risk Sciencedirect |

| Format: ePub Book |

| Number of Pages: 333 pages Using The Assembly Line Balancing Procedure |

| Publication Date: October 2017 |

| File Size: 3.4mb |

| Read Multi Objective Assembly Line Balancing Considering Ponent Picking And Ergonomic Risk Sciencedirect |

|

Lean Manufacturing Line Balancing And How To Improve With Digital Tools

| Title: Lean Manufacturing Line Balancing And How To Improve With Digital Tools |

| Format: PDF |

| Number of Pages: 150 pages Using The Assembly Line Balancing Procedure |

| Publication Date: May 2019 |

| File Size: 3.4mb |

| Read Lean Manufacturing Line Balancing And How To Improve With Digital Tools |

|

Modified Product Layout And Assembly Line Balancing Example

| Title: Modified Product Layout And Assembly Line Balancing Example |

| Format: PDF |

| Number of Pages: 298 pages Using The Assembly Line Balancing Procedure |

| Publication Date: November 2017 |

| File Size: 1.3mb |

| Read Modified Product Layout And Assembly Line Balancing Example |

|

Om Calculation Line Balancing Calculation

| Title: Om Calculation Line Balancing Calculation |

| Format: PDF |

| Number of Pages: 316 pages Using The Assembly Line Balancing Procedure |

| Publication Date: June 2018 |

| File Size: 1.4mb |

| Read Om Calculation Line Balancing Calculation |

|

Pdf Application Of Line Balancing To Minimize The Idle Time Of Workstations In The Production Line With Special Reference To Automobile Industry

| Title: Pdf Application Of Line Balancing To Minimize The Idle Time Of Workstations In The Production Line With Special Reference To Automobile Industry |

| Format: ePub Book |

| Number of Pages: 320 pages Using The Assembly Line Balancing Procedure |

| Publication Date: January 2017 |

| File Size: 1.5mb |

| Read Pdf Application Of Line Balancing To Minimize The Idle Time Of Workstations In The Production Line With Special Reference To Automobile Industry |

|

Production time is 480 minutes and the required daily output is 50 units. It is a technique to reduce imbalance between workers and workloads in order to accomplish required run rate HJay and RBarry 2006. Otherwise resources should be reallocated or rearranged to remove bottlenecks or excess capacity.

Here is all you need to read about using the assembly line balancing procedure Line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. Assembly-Line Balancing Assembly-Line Balancing Objective is to minimize the imbalance between machines or personnel while meeting required output Starts with the precedence relationships Determine cycle time Calculate theoretical minimum number of workstations Balance the line by assigning specific tasks to workstations. Line balancing is usual practice to resolve problems occurred in assembly line. What is line balancing om calculation line balancing calculation assembly line balancing pdf modelling of simple assembly line balancing problem type 1 salbp 1 with machine and worker constraints pdf application of line balancing to minimize the idle time of workstations in the production line with special reference to automobile industry lean manufacturing line balancing and how to improve with digital tools Using the assembly-line balancing procedure which of the following is the theoretical minimum number of workstations if the task times for the eight tasks that make up the job are 7 4 7 8 9 4 3 and 6 minutes and the cycle time is 8 minutes.

0 Comments